It’s frequent data that wooden comes from bushes. What will not be so obvious is the construction of the wooden itself, and the personal parts that make up any given piece of lumber. Not like a largely homogenous piece of foamboard, MDF, or different man-made materials, wooden is a natural materials and has many distinct traits which will probably be useful to study.

HARDWOODS AND SOFTWOODS

A direct and broad distinction that may be made between varieties of bushes (and wooden) is the label of hardwood or softwood. That is considerably of a misnomer, because the label is definitely only a separation between angiosperms (flowering vegetation equivalent to maple, oak, or rosewood), and conifers (cone-bearing bushes equivalent to pine, spruce, or fir). Hardwoods (angiosperms) have broad-leaved foliage, and are typically deciduous—that’s, they lose their leaves within the autumn. (Nonetheless, many tropical hardwood species exist that are evergreen—they keep their leaves year-round.) Moreover, hardwood bushes are likely to have a branched or divided trunk, known as a dendritic type.

Softwoods (conifers) are likely to have needle or scale-like foliage, although in some unusual cases, they’ll have relatively broad, flat leaves, equivalent to Kauri (Agathis australis). Most softwood bushes are evergreen, nonetheless, some conifers equivalent to larch or cypress lose their foliage within the autumn, (therefore the frequent identify “bald-cypress”). Softwoods are likely to have a single, dominant, straight trunk with smaller aspect branches, known as an excurrent type—this cone-shaped progress type helps bushes in temperate climates shed snow. Once more, there are a number of conifers which might be an exception to this progress type, equivalent to Cedar of Lebanon (Cedrus libani).

The confusion in labels arises in that the wooden of angiosperms is just not at all times laborious (a evident instance is Balsa, which is technically categorised as a hardwood), whereas the wooden of conifers is just not essentially at all times tender, (an instance of a comparatively laborious softwood could be Yew). Nonetheless, as a rule of thumb, hardwoods are after all usually more durable than softwoods, and the label remains to be helpful to differentiate between two broad teams of bushes and sure traits of their wooden.

TREE GROWTH

To begin off with, let’s suppose that we’ve got a tiny little sapling, simply beginning out on its journey to turn out to be a grand tree. In addition to the fundamentals of the roots, the principle stem (trunk), and the leaves and branches, there are rising factors on the ideas of the stems and roots, known as apical meristems. These rising factors, by way of cell division, are liable for the vertical progress in bushes. Moreover, sandwiched between the bark and the inside wooden is a skinny layer or sheath known as the vascular cambium or lateral meristem—normally referred to easily because the cambium. This tiny, seemingly magical layer is liable for virtually all the horizontal progress on a tree. The cambium consists of reproductive cells that, by cell division, kinds new bark outward, and likewise new wooden inward. It’s the seasonal rising exercise of the cambium that’s liable for the formation of progress rings seen in wooden: in temperate zones, the cambium is most lively within the spring, (this wooden is usually known as springwood or earlywood), with progress slowing in the summertime, (known as summerwood or latewood), and fully ceasing within the winter. These variations in rising cycles from 12 months to 12 months type annual rings, that are a fairly correct indicator of a tree’s age.

| Softwoods: latewood tends to be darker, denser, and has smaller diameter tracheids; earlywood is lighter, softer, and has bigger diameter tracheids | Hardwoods (ring-porous): latewood has smaller and fewer frequent pores; earlywood has bigger, extra quite a few pores |

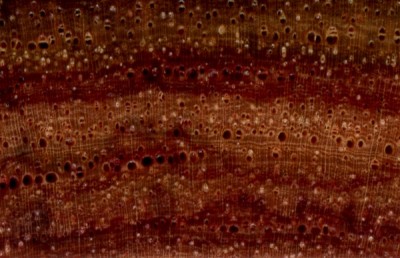

| Redwood (endgrain 10x) | Paulownia (endgrain 10x) |

| Observe the a lot wider earlywood zone in softwoods such because the Redwood (Sequoia sempervirens) pictured on the left as in comparison with hardwoods like Paulownia (Paulownia tomentosa) on the proper. When a tree grows slower than common, (maybe resulting from an unfavorable rising website), the earlywood and latewood zones turn out to be condensed. This distinction explains why slower rising softwoods are typically stronger, (the weaker earlywood zones are narrower), whereas slower rising ring-porous woods like oak or ash are typically weaker, (the stronger latewood zones are narrower). |

In tropical zones, the place temperature and seasonal differences are minimal, wooden can fully lack discernible rings, or they might correspond with varied wet seasons, and thus are extra safely known as progress rings, and never strictly as annual rings.

An endgrain view of Avodire (Turraeanthus africanus), a tropical African hardwood species, reveals an general lack of discernible progress rings or earlywood and latewood zones.

SAPWOOD AND HEARTWOOD

Because the cambium kinds new wooden cells, they become totally different sizes, shapes, and orientations to carry out quite a lot of duties, together with meals storage, sap conduction, trunk energy, and so forth. When a tree is younger, sure cells inside the wooden are alive and able to conducting sap or storing vitamins, and the wooden is known as sapwood. After a interval of years, (the quantity can significantly fluctuate between species of bushes), the tree not wants the complete trunk to conduct sap, and the cells within the central a part of the stem—starting on the core, or pith—start to die. This lifeless wooden which kinds on the middle of the trunk is thus known as heartwood. The transition from sapwood to heartwood is accompanied by the buildup and buildup of assorted deposits and substances, generally known as extractives. Most notably, these extractives are liable for giving the heartwood its attribute coloration: the jet-black coloration of Ebony (Diospyros spp.), the ruby-red of Bloodwood (Brosimum rubescens), or the chocolate-brown of Black Walnut (Juglans nigra)—all owe their vivid hues to their respective heartwood extractives. (With out extractives, the sapwood of almost all species of wooden is a pale coloration, normally starting from white to a straw-yellow or gray coloration.)

Heartwood extractives, like these discovered on this pattern of Tulipwood (Dalbergia decipularis) present a cornucopia of colours and distinctive wooden properties. However heartwood extractives are liable for extra than simply coloration; extractives improve (to various levels) the heartwood’s resistance to rot and decay, in addition to giving it added stability and hardness. (Sapwood has just about no resistance to decay—which, being basically alive within the tree, is just not wanted.) From a organic standpoint, it’s simple to see the advantages that heartwood brings to the tree because it grows taller and broader—and by the way, many of those similar advantages translate into benefits for woodworkers as nicely. Nonetheless, it must be famous that the transition space from sapwood to heartwood, generally known as the sapwood demarcation, can fluctuate from gradual to very abrupt: this may be necessary in wooden tasks the place decay resistance is required. A transparent line of demarcation helps stop the inadvertent inclusion of sapwood, and minimizes the chance of subsequent rotting or structural harm.

PLANES OR SURFACES OF WOOD

When discussing processed wooden and lumber, it’s obligatory to grasp which floor of the wooden is being referred to. Working inside the scope of progress rings already mentioned, and their orientation inside the tree’s trunk, there are three main planes, or surfaces, which might be encountered in processed wooden. The primary wooden floor is the endgrain, (which is by far probably the most helpful aircraft for wooden identification functions). This floor is usually known as the transverse floor, or the cross part. This aircraft is generally self-explanatory: in processed lumber, it’s the part the place a board is often considered on its finish, and round progress rings could also be clearly noticed. For the sake of simplicity and readability, all references on this web site will seek advice from this wooden aircraft because the endgrain. The second main wooden aircraft is the radial floor. (Consider the phrase radiate: the wooden floor radiates out from the middle of the log like spokes on a wheel, and crosses the expansion rings at a more-or-less 90° angle.) This floor goes by numerous names, and is usually known as vertical grain, or the quartersawn part. The rationale for such naming is that when sawing a log, it might be sawn into quarters alongside the size of the log, forming 4 lengthy, triangular, wedge-shaped items. Subsequent, boards are sawn from every wedge on alternating sides, leading to boards which—when considered from the endgrain—have progress rings which might be perpendicular to the face and run vertically. Once more, for simplicity and readability, most references on this web site will seek advice from this wooden aircraft because the quartersawn floor. That is maybe not the usual scientific terminology used, nevertheless it’s the commonest description used amongst sawyers and woodworkers. The third and remaining floor is the tangential floor. (Consider the phrase tangent: the wooden floor is kind of on a tangent with the expansion rings.) This aircraft is usually known as the flatsawn or plainsawn floor. The rationale for such naming comes once more from the method of sawing the log. The traditional or “plain” technique of sawing a log is to chop straight by way of in a repetitious sequence, leaving the log flat all through the complete course of. (That is additionally generally known as through-and-through sawing.) Most subsequent references on this web site will seek advice from this wooden aircraft because the flatsawn floor.

This pattern of Butternut (Juglans cinerea) fashions the three wooden surfaces nicely. Observe the straight and constant grain sample proven on the quartersawn floor on the proper as in comparison with the comparatively wild flatsawn floor on high. The endgrain on the left reveals the arc of the expansion rings.

GRAIN APPEARANCE

Though quartersawn and flatsawn surfaces are named after their authentic technique of sawing, in follow, the phrases sometimes simply seek advice from the angle of the expansion rings on a chunk of processed lumber, with something between 45° and 90° being known as quartersawn, and something between 0° and 45° usually being flatsawn, no matter how the log was truly milled. There’s generally an intermediate angle generally known as riftsawn or bastard grain, which corresponds with progress rings angled between 30° to 60°, (with 45° being the typical). Though it’s known as riftsawn, sawyers will not often if ever particularly noticed up a log with a purpose to get such an angle; normally the identify merely serves as a handy time period to explain wooden that’s not completely quartersawn. Moreover, the time period face grain normally denotes probably the most predominant/widest wooden aircraft on any given piece of lumber (excluding the endgrain), and doesn’t seek advice from any particular lower. By observing the angle of the expansion rings—as when taking a look at a stack of boards the place solely the endgrain is seen—a fairly correct prediction of the looks of the face of the board could be made. Likewise, in lots of cases the place solely the face of a board is seen, the endgrain could also be extrapolated by “studying” the grain sample. Every grain lower has various strengths and weak spot, and is utilized in totally different purposes.

Quartersawn boards are very uniform in look and are good for lengthy runs of flooring the place the boards have to be butted end-to-end with minimal disruption in look. Quartersawing additionally produces the stablest boards with the least tendency to cup or warp with modifications in humidity, which could be very helpful in lots of purposes, equivalent to for the rails and stiles of raised panel doorways. Nonetheless, due to the additional dealing with concerned with processing the log, and the upper waste issue, quartersawn lumber tends to be dearer than flatsawn lumber. Most would agree that flatsawn boards—with their attribute dome-shaped cathedral grain—are likely to yield probably the most visually placing patterns, (and it ought to come as no shock that many veneers are additionally rotary-cut from logs to breed this look). Flatsawn boards are additionally out there in wider dimensions than quartersawn inventory, and are well-suited to purposes equivalent to raised or floating panels, or different areas the place width or look are necessary. Riftsawn wooden lies someplace between these two aforementioned grades. It has a uniform look that’s similar to quartersawn wooden—and it’s almost as secure too. On giant sq. posts, equivalent to these used for desk legs, riftsawn wooden has the additional benefit of showing roughly the identical on all 4 sides, (because the rings on every of the surfaces are all at roughly 45° angles to the face), whereas quartersawn squares would have two sides that show flatsawn grain, and vice versa.

RAYS

A dialogue on quartersawn and riftsawn lumber wouldn’t be full with out mentioning probably the most important visible distinction between the 2: presence (or absence) of rays; or maybe extra precisely, the conspicuous presence of rays on the face grain of the board, identified generally as ray fleck, or ray flakes.

|

| Observe the lighter coloured rays radiating out from the pith on this pattern of Holm Oak (Quercus ilex). Ray fleck is just obvious in areas on the face of the board which might be almost completely quartersawn, with the flat and rift sawn areas on the left two thirds obscuring the rays underneath a decrease profile. |

In the identical manner that quartersawn surfaces radiate out from the middle of the log, (therefore the time period radial floor), rays are additionally oriented in the identical route; because of this, though rays are at all times technically current within the wooden, they turn out to be most seen and pronounced on quartersawn surfaces. (Moreover, endgrain drying checks additionally are likely to happen alongside the rays.) However despite the fact that just about all woods have rays, solely the species with vast, conspicuous rays will produce dramatic ray fleck on the quartersawn floor. Maybe the most important rays are discovered on woods like Leopardwood (Roupala spp.) and Lacewood (Panopsis spp.), so named for the very good ray fleck seen on their quartersawn surfaces.

|

| The rays seen on this endgrain view of Lacewood (Panopsis spp.) are so giant and prevalent, they may simply be mistaken for progress rings. |

Home woods like oak (Quercus spp.) and sycamore (Platanus spp.) even have simply observable rays; different woods have very modest but seen ray fleck on quartersawn surfaces, equivalent to Black Cherry (Prunus serotina). It must be famous that ray fleck is just not at all times greeted with enthusiasm: the exact same characteristic which will entice somebody to buy quartersawn oak might also repel one other away. In some cases—equivalent to for hardwood flooring the place a subdued or constant grain sample could also be desired—ray fleck could also be considered as objectionable or distracting. For that reason, riftsawn woods, mostly White Oak (Quercus alba), is sometimes supplied as a way to reap the advantages of uniformity and stability of quartersawn lumber with out the generally detracting rays.