1. Superior Screw Holding

As a result of the core layers of Baltic birch are literally veneers of birch (fairly than a softer, secondary wooden) and type a void-free core, screws chew and maintain with 100% of their threads. Conversely, conventional veneer core plywood has voids and can be made up of softer supplies so screws don’t get an opportunity to clench one of the best they’ll. You additionally may discover sheet items made with MDF (medium-density fiberboard) core, and although it’s 100% stable, MDF is comfortable and simply doesn’t have the screw-holding energy of Baltic birch.

Stable joinery like half-blind dovetail joints are usually not solely potential with Baltic birch, however they appear good too.

2. Cleaner Joinery

Tipping the hat as soon as once more to the uniform birch veneer layers of the core, you’ll get clear dadoes, rabbets, dovetails, miters, and fingers for robust and, when applicable, nice wanting joints. As a result of the core is freed from voids, your joinery additionally received’t endure from glue hunger—they’ll get 100% glue protection. Something you construct out of Baltic birch ought to final , very long time.

3. Improved Energy and Stability

All plywood runs the chance of warping, and the most typical sort of warp in plywood is bowing. Baltic birch is just not immune, it’s nonetheless a wooden product. Nevertheless, Baltic birch has the chances stacked in its favor a lot better than different plywood, mainly in 1/2″ and three/4″ thickness. The cross-banded layers of 1.5 mm thick birch veneer makes the sheets balanced, which guarantees a flatter product. Nevertheless the thinner sheets, like 1/8″ and 1/4″, merely is not going to stay flat in giant items—and that is no shock. That’s often not an issue although as a result of these are often utilized in purposes like drawer bottoms and cupboard backs the place they’re reduce all the way down to smaller sizes or captured in dadoes and rabbets. It must be apparent that the thicker sheets are extra steady as a result of they’ve extra plies. 3/4″ Baltic birch specifically received’t change a lot in width or size, that’s why it’s nice for jigs and fixtures that want to keep up accuracy through the years.

Baltic birch edges don’t look too dangerous when formed, sanded and completed.

4. Enticing Look

One of many lucky advantages to Baltic birch, too, is that you would be able to depart the sides uncovered should you just like the look. As a result of the core is freed from voids and all birch, the uncovered edges typically have an look that works for the mission, and this protects you time and materials—no must spend effort and time on making use of edge tape or stable edge banding except you need to. Merely sand and end the sides as they’re. The face and again could be stained whenever you want a distinct coloration. Like stable birch lumber, for it to stain evenly with an oil based mostly pigment stain you’ll want to use a stain controller or a wash coat of de-waxed shellac. In any other case use dye for even coloration. To maintain the uniform, mild coloration as an alternative, merely end Baltic birch with a fundamental clear high coat of lacquer or polyurethane.

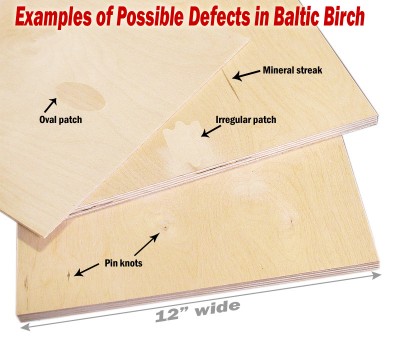

5. Thicker Face Veneer with Cheap High quality

With shut inspection of Baltic birch, you need to discover that the face and again veneers are remarkably thicker than the veneers you’ll see on conventional cabinet-grade plywood. Sadly, it’s well-known that cupboard grade plywood veneer faces are dismally skinny, which makes them straightforward to wreck and straightforward to sand by way of. However not so with Baltic birch. Outer veneers are good and thick. As for the looks, there are a number of grades of Baltic birch out there, however we most frequently carry the second highest grade which is BB/BB. BB/BB means each the face and the again veneers are single piece veneers with no splices. Each face and again veneers can have as much as 6 small color-matched patches (egg sized footballs or one other form), some mild mineral streaks or tight pin knots.

6. Accepts Paper Again Veneer for Extra Ornamental Initiatives

When you like all the pieces about Baltic birch besides its outer birch look (or occasional “soccer” patches), no drawback. You may face this plywood with any form of lovely wooden veneer. Make sure to veneer each side to keep up its stability.

7. It’s Simply the Factor for Laser Reducing and Engraving

It’s one of many few kinds of wooden that may are available in giant sufficient sheets and but be constantly dense by way of its thickness to be reduce with a laser. Something from components for architectural fashions to paintings to schmaltzy engraved knick-knacks.

The draw back is that 1/8″ and 1/4″ thick Baltic birch can’t keep completely flat. It does cup or warp. It’s not as a result of it’s dangerous plywood however simply an impact of the scale. It’s skinny and large. Not combo for getting wooden to put flat.

So what do you do? Make a body or jig that presses it flat and matches your laser cutter. Typically all you want is to tape it all the way down to a chunk of MDF.

Normal Baltic Birch Grades:

What To Know: plywood is graded on the looks of the face and again veneers solely (not the core). The higher aspect is known as the face, the poorer aspect is known as the again. These grades listed under learn “face/again.”

B/BB: Single piece face and again veneer. Face veneers are thought-about clear and freed from defects with a light-uniform coloration. Again permits 3-6 coloration matched patches, that are oval in form and egg sized. Internal cores are stable birch single piece veneers.

BB/BB: Single piece face and again. Each face and again veneers enable 3-6 small color-matched patches on common and a few mild mineral streaks. Tight pin knots could also be current. Internal cores are stable single piece veneers.

BB/CP: Single piece face and again. The “CP” again veneers are downgraded from “BB” grade veneers, which permit for limitless patches and sound knots, however doesn’t enable for open defects. Internal cores are stable birch single piece veneers.

CP/CP: Single piece face and again. Face and again grade veneers enable limitless sound knots and repaired splits and limitless patches. The panel is sound each side and designed for laminating.

C/C: Patches, open knots, and small veneer cut up allowed. Veneer lap and small core voids permitted. This panel is just not sanded and can be used for structural functions.