Tarmo Räty and Maria Riala study the certification choices of Nordic producers and draw some lessons

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to share on Pocket (Opens in new window)

- Click to email this to a friend (Opens in new window)

- Click to print (Opens in new window)

Blogs.lse.ac.uk- The efficiency of environmental communication should be built throughout business practices. Natural Resources Institute Finland (Luke) (www.luke.fi) has studied this issue by interviewing companies in the Nordic woodworking industry and by analysing recent developments in environmental performance measures.

Wood is a renewable raw material, and thus the environmental performance of wood product companies has the potential to give them a competitive edge. The efficient communication of their environmental performance in marketing campaigns could help them create new business. In our recent study of the Nordic woodworking industry, we investigated whether the companies had made the most of the possibilities to communicate their environmental performance. The in-depth interviews gave us many insights into environmental communication.

Ecolabelling of forest products

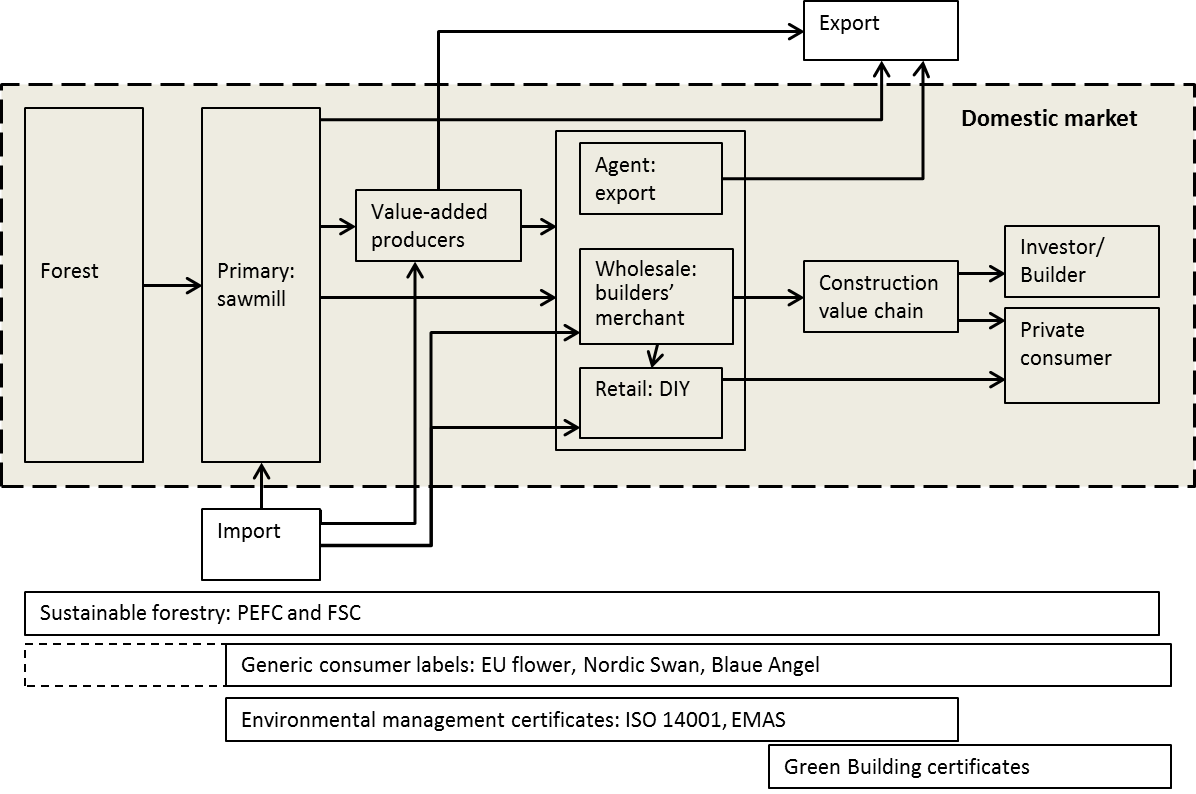

The wood industry in the Nordic countries is an important supplier to the European markets. The raw material basis is predominantly Nordic coniferous forests. About 70 per cent of the sawn timber is used for construction. This value chain and key environmental performance measures along the chain are illustrated in Figure 1. The type of measurements used is an important choice that maintains efficient communication throughout the value chain. The tricky questions are when to make use of forestry-related measures only or generic environmental labels, how to contribute through green building certificates, or whether regular environmental management certificates will suffice.

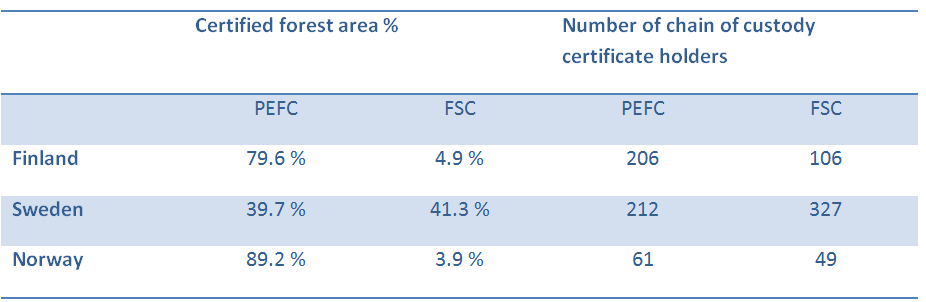

The companies interviewed most commonly used forest certification or environmental management certificates as environmental performance measures. There are two competing forest certification systems, PEFC and FSC. Their purpose is to show that the wood comes from sustainably managed forests. They both also offer chain of custody certification. The coverage of these certification schemes varies a great deal regionally and along the value chain; the Nordic coverage is presented in the Table. PEFC is the largest globally in certified hectares, but FSC is a more frequently used chain of custody certificate on key export markets of the Nordic woodworking industry. Probably due to the good availability of PEFC-certified wood in the Nordic countries, PEFC was more often used also among our interviewees, although some used FSC or both. The interviewees usually recognised generic consumer labels (e.g. EU flower, Nordic Swan) but they were rarely used by the companies. Even though green building certificates (e.g., LEED, BREEAM) could be powerful tools to promote the use of wood, they were not yet found in the environmental communication toolbox of the Nordic woodworking industry.

Table: Forest certification in Nordic countries

Motivation to certify products

A gap exists between the use and perceived usefulness of environmental performance measures in our data. Although forest certification and environmental management certificates were frequently used, the interviewees did not always consider them to be useful.

This brings us to the question of why companies use environmental performance measures. Our study suggests several reasons. Often, they are used to prove the green credentials of the company. This was seen as particularly necessary in export markets such as the UK. Interestingly, our interviewees thought that B2B customers demanded more information about environmental performance than did consumers. Even in this case, the motivation was questioned e.g. “Why pay more to show something that everybody already knows? But then, someone starts off certifying and customers think that this is great and then everyone has to do it.” This type of scepticism was present especially on domestic markets.

Shift to the quantitative environmental performance measures

Virtually all environmental performance measures used by the wood product industry are of a qualitative nature. Given that sustainably sourced wood has sequestered carbon from atmosphere and substitutes fossil carbon intensive materials such as concrete and steel, there are opportunities to elaborate on the quantitative impacts. Regular quantitative measures are single-valued product environmental footprints (PEFs, see) like carbon or water footprints and environmental product declarations (EPDs, see. ) that consider several factors of environmental performance over the products’ whole life cycle. Aside carbon related global warming potential, eutrophication, acidification of water and soils, abiotic depletion and ozone depletion and creation are usually accounted for in EPDs.

PEFs and EPDs were rarely used by our interviewees, but this situation might change in the near future, especially for construction products. Standards to compile and communicate are currently under development. ISO has a published standard for carbon footprints (ISO 14067) and BSI’s PAS 2050 serves the same purpose. Concerning the environmental product declarations, the European Committee for Standardization (CEN) has developed a whole series of standards for the sustainability of construction works. Among the Nordic countries, Norway has already taken good steps towards compiling EPDs for construction products. A game changer for the demand for EPDs in Norway has been the green building certificate BREEAM-NOR, which gives credits when main materials used in a construction project have EPDs (Tellnes, 2015).

The obvious question is what could be done to improve the efficiency of environmental communication in the Nordic wood product industry. Above all, there is room to shift strategic orientation from sustainable forest management certification to messages that would more effectively motivate the modern urban end-users to make environmentally friendly choices. Environmental issues as such are complex, and forest management issues are rather specific in nature. Therefore, firms should continue to issue sustainable forest management certificates securing the availability of the downstream chain of custody-certified wood products, but shift also to a more general environmental argumentation on the end-user markets. Second, instead of using almost exclusively qualitative arguments, quantitative environmental footprints and EPDs open efficient ways to communicate both directly with the public and through decision-makers in the construction value chain.

Vietnam Plywood

Vietnam Film Faced Plywood