Hunker– Plywood is the best-known type of _sheet good_—wood building materials sold in sheet form rather than in boards. Sheet goods generally come in 4 x 8-foot sheets or panels, and in thicknesses such as 1/4-inch, 1/2-inch, and 3/4-inch. Made with thin layers or small pieces of wood glued (laminated) together, sheet goods have replaced solid-lumber boards for much of modern construction, and they offer some important advantages over lumber, one being their large size. In fact, you can think of plywood and other sheet goods as really big, flat boards that you can cut to any size you need.

What Is Plywood and How Is It Made?

Plywood is a sandwich of thin layers, or plies, of wood glued and pressed together to form a very strong and dimensionally stable panel. Dimensionally stable means that the panel doesn’t expand or contract much (as solid wood is highly prone to doing) and you can count on it having consistent sizing and thickness throughout the material.

Plywood gets this stability from a construction technique called cross-graining. Instead of having the wood grain of each plywood layer running in the same direction, cross-graining alternates each layer so the wood grain of one layer is perpendicular to the next. Wood grain expands (and contracts) more side-to-side than it does end-to-end; cross-graining minimizes this movement because the alternating layers are always expanding or contracting in opposite directions.

Layered construction is also the secret to making plywood beautiful and affordable at the same time. Since only the two outer layers—called face veneers—are visible, plywood manufacturers use the best looking and thinnest plies on the outside and use less attractive (and often lower-quality) wood for the inner layers. The benefit to you as a consumer is that the cost of premium plywood is about half of what you’d pay for the same amount of material in solid lumber (especially hardwood lumber).

Types of Plywood

As a manufactured product, plywood comes in many different types for different applications. These can be broken down into two main groups: plywood for construction and plywood for woodworking projects, such as furniture and cabinets. Construction plywood generally is rougher and less attractive and has fewer plies than finish-type (sometimes called cabinet-grade) plywood. Construction plywood typically is made only with common grades of softwood, such as Douglas fir, while finish plywood often contains some hardwood.

A few common types of plywood and their uses include:

- Sheathing: Standard construction plywood used for wall sheathing, roof decking, floor structures (subflooring) and general rough construction where looks and surface imperfections aren’t important.

- Sanded plywood: General-purpose “project” plywood with decent-looking face veneers that have been sanded smooth. Good for basic projects around the house, such as utility shelves or workbench tops, and anything that will be painted.

- Subflooring: 3/4-inch-thick construction plywood with tongue-and-groove edges that lock together to create a solid floor surface.

- Exterior: Various grades of construction plywood intended for outdoor use. Only pressure-treated exterior plywood is rot-resistant.

- Cabinet-grade: Also called furniture-grade or hardwood plywood, generally a higher-quality panel with attractive hardwood face veneers suitable for staining. Lower grades have softwood interior plies; better grades have all-hardwood plies and face veneers. Used for all types of woodworking projects where looks count.

- Marine: Premium plywood made with waterproof glue to prevent the plies from delaminating due to exposure to water. Commonly misrepresented as “waterproof,” but the wood itself is not treated for rot-resistance. Designed for boatbuilding but also popular for outdoor furniture projects.

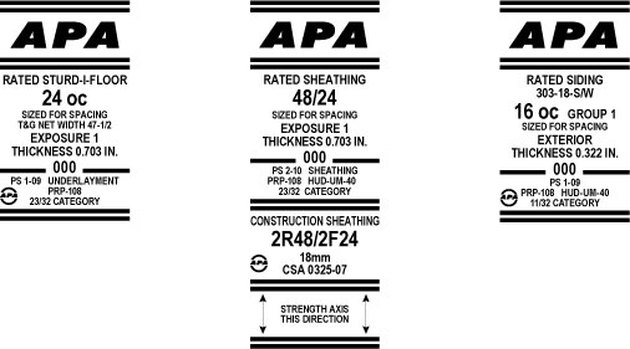

Plywood Grading and Exposure Ratings

Plywood grades generally refer to the quality and appearance of the face veneers. Each panel gets one grade for the front and one for the back. Most systems use grades A through D, with A being the best (if you see an “N” grade, it’s basically an A or better), but some use numbers 1 through 3 (1 is the best). Here’s what the grades mean (keep in mind that grading standards vary by manufacturer):

- A: Smooth, paintable surface with no knots and no surface repairs.

- B: Similar to A but may contain tight (not loose) knots up to 1 inch and may include repairs (made with wood putty or football-shaped wood patches).

- C: May contain tight knots up to 1 1/2 inches, as well as surface repairs.

- D: May contain large and/or loose knots, voids without surface repairs, splits and other flaws.

Exposure rating is a form of grading that indicates suitability for outdoor exposure, and there are only two ratings: Exterior and Exposure 1. Both ratings indicate the plywood is made with water-resistant glue. Exterior panels are rated for repeated wetting and drying cycles and internal moisture content that can be higher than 19 percent. Exposure 1 panels can be exposed to wet conditions only for a limited time, such as during house construction, and should not exceed a moisture content of 19 percent for long periods.

A plywood grade including the letter X, such as the commonly sold CDX plywood, indicates Exposure 1 rating. Plywood intended for ground contact must be pressure-treated. If a plywood panel does not carry an exposure rating, it is for indoor use only.

Other Types of Sheet Goods

Plywood is generally the strongest and most versatile sheet good, but it’s not the smoothest, flattest or cheapest. Other common types of sheet goods can be a better choice for specific applications:

- MDF: Medium-density fiberboard; made with tiny wood particles and sawdust bound with adhesive and sanded almost glass-smooth. MDF cuts and sands very nicely and has a very hard, flat surface that’s great for tabletops and other flat surfaces where looks aren’t important (it looks like a brown paper bag). The material is highly prone to water damage, so don’t use it anywhere near moisture.

- Particleboard: Similar to MDF but made with slightly coarser pieces of wood. The top and bottom surfaces are equally flat and smooth to MDF’s, but the edges of particleboard don’t cut and sand as cleanly. Around the house, particleboard is primarily used as a substrate for countertop materials such as plastic laminate. It’s also found on low-quality cabinet boxes and furniture parts.

- Hardboard: Thin panel made with tiny wood fibers and adhesive. The top surface is even smoother and harder than MDF or particleboard; the core and back surface have a softer, fibrous texture. Hardboard is 1/8 or 3/16 inch thick and is somewhat flexible, making it handy for craft projects and as a backing for bookshelves. “Pegboard” is a hardboard material with predrilled holes for sticking in pegs, hooks and other hanging hardware.

- OSB: Oriented strand board; also called wafer board or chipboard, made with thin wafers and chips of wood bound with adhesive. OSB is used in many of the same applications as construction plywood but primarily for sheathing and subflooring. By far the ugliest of the sheet goods, OSB costs less than standard plywood and is best for uses where it won’t be seen.