In a proof-of-concept collaboration between TWI Ltd and the University of Cambridge and enabled by the Construction Innovation Hub, researchers have developed a sustainable course to hitch timber parts utilizing linear friction welding quickly. Two years into the mission, they’ve been in a position to be part of items of wooden in two to 3 seconds by rubbing them collectively at excessive speeds, with the ensuing welded joint being stronger than typical adhesives and as sturdy because of the timber itself. Scaled up, this welding method may very well be utilized in constructing development and high-volume manufacturing of merchandise reminiscent of furnishings and packaging.

Timber development affords a chance to seize carbon dioxide from the environment and retailer it long-term in buildings. Mass timber development with engineered timbers affords additional benefits associated to the velocity of development by off-site prefabrication and speedy on-site meeting. Each these advantages of sustainability and velocity could be additional enhanced by growing fast timber becoming a member of methods. Timber joints counting on adhesives, for instance, require drying (over a number of hours), could current well being hazards, and restrict the timber’s end-of-life choices.

Together with trade companions TWI Ltd, Dr. Darshil Shah and Dr. Michael Ramage from the Department of Architecture and the award-winning team behind the HappyShield open-source PPE design have developed a course of to hitch timber parts utilizing linear friction welding quickly. In distinction with conventional strategies reminiscent of adhesives, linear friction welding of wooden can reliably produce high-quality joints with excessive tolerances and doesn’t require any filler or adhesive materials.

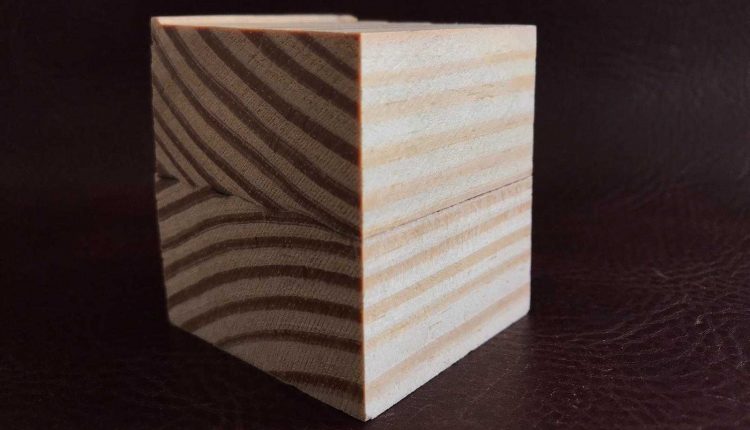

On this energy-efficient course of, joints are produced by urgent and rubbing two timber surfaces collectively at a excessive frequency (50-150 Hz). The ensuing friction and warmth softens and re-sets lignin, the pure ‘glue’ in plant supplies, and mechanically interlocks the mobile materials, inflicting the ‘welding.’ In simply two to 3 seconds, the fused timber joint is stronger than typical adhesives and even stronger than the native wooden.

“Think about you’re out strolling on a chilly day and wish to heat up your palms; you’re prone to rub your palms collectively to generate warmth. How do you produce extra warmth?” asks Dr. Shah. “Rub your palms sooner (frequency), push your palms in opposition to one another with extra drive (strain), rub your palms for longer (time) and transfer your palms over an extended distance (amplitude). Equally, in wooden welding, to generate extra friction and warmth, these are the 4 principal manufacturing parameters we are able to management.”

This method could be utilized to planed/sawn wooden and CLT (Cross Laminated Timber), which is the important thing timber-origin materials utilized by the crew from the Dept of Structure in their project.

The crew continues to discover how these parameters change the method and why it appears to work otherwise with totally different woods. This can assist them discover the appropriate supplies and manufacturing parameters to optimise the method and scale it up for various functions, reminiscent of development and manufacturing. On this preliminary proof-of-concept examine, the crew demonstrated the suitability of the method on quite a lot of hardwoods, softwoods, and engineered woods (e.g., MDF) utilizing varied grain orientations. Extra not too long ago, they’ve centered on beech, a widely-used European hardwood in development and furniture-making. Whereas this course of has been examined at smaller scales, the crew is hopeful that it’s appropriate for becoming a member of a lot bigger items of wooden and can subsequently be well-suited to off-site timber development for buildings.

Since October 2020, the crew has continued to work collectively by studentships to advance the science and know-how of wooden welding. Led by Dr. Darshil Shah (CNMI), Dr. Eleni Toumpanaki (now at Bristol College), and Dr. Kate Franklin (TWI). Two final-year undergraduate mission college students at Cambridge, Mads Studholme and Jason Chang, are investigating becoming a member of bamboos, softwood pines, and even welding totally different woods, in addition to learning their resistance to moisture and their fireplace efficiency. Early outcomes proceed to be promising, and the crew seems to be ahead to demonstrating the welded elements at bigger scales.

This analysis types a part of the Centre for Digital Built Britain’s (CDBB) work on the College of Cambridge. It was enabled by the Building Innovation Hub, of which CDBB is a core associate, and funded by UK Research and Innovation (UKRI) by the Industrial Strategy Challenge Fund (ISCF).

The collaborating crew:

- College of Cambridge: Dr. Darshil Shah, Dr. Michael Ramage, Mads Studholme, and Jason Chang

- College of Bristol: Dr. Eleni Toumpanaki (beforehand UCam)

- TWI: Dr. Kate Franklin, Dr. Scott Andrews, Dr. Bertrand Flipo, and Dr. Steve Dodds

- College of Edinburgh: Dr. Thomas Reynolds (beforehand UCam)