Hemp can seize atmospheric carbon twice as successfully as forests whereas offering carbon-negative biomaterials for architects and designers, in line with Cambridge College researcher Darshil Shah.

“Quite a few research estimate that hemp is among the finest CO2-to-biomass converters,” stated Shah, who’s senior researcher on the Centre for Natural Material Innovation at Cambridge.

“It is much more efficient than timber,” he stated. “Industrial hemp absorbs between 8 to fifteen tonnes of CO2 per hectare of cultivation.”

“Compared, forests usually seize 2 to six tonnes of CO2 per hectare per 12 months relying on the variety of years of progress, the climatic area, the kind of timber and so on.”

Carbon-negative bioplastics and development supplies made out of the plant can be utilized to “exchange fibreglass composites, aluminium and different supplies in a spread of purposes,” he added.

The Centre for Pure Materials Innovation, a part of Cambridge College’s Division of Structure, conducts analysis into biomaterials in an effort to “remodel the best way we construct to realize zero carbon emissions.”

Hemp is a “multi-purpose crop”

Shah’s work covers engineered wooden, bamboo and pure fibre composites in addition to hemp, which he described as “a multi-purpose crop that provides supplies and assets in a number of kinds.”

Hemp, or industrial hemp, is quite a lot of the Hashish sativa plant however comprises very low ranges of the psychoactive compound tetrahydrocannabinol (THC) in comparison with marijuana, which is one other selection.Related storyMycelium is “part of the solution” to carbon-negative buildings

The fast-growing plant has been grown for 1000’s of years for its fibres, which had been historically used for rope, textiles and paper.

At present it’s more and more getting used to make bioplastics, development supplies and biofuels in addition to merchandise containing cannabidiol (CBD), an lively ingredient that’s touted for its alleged well being advantages.

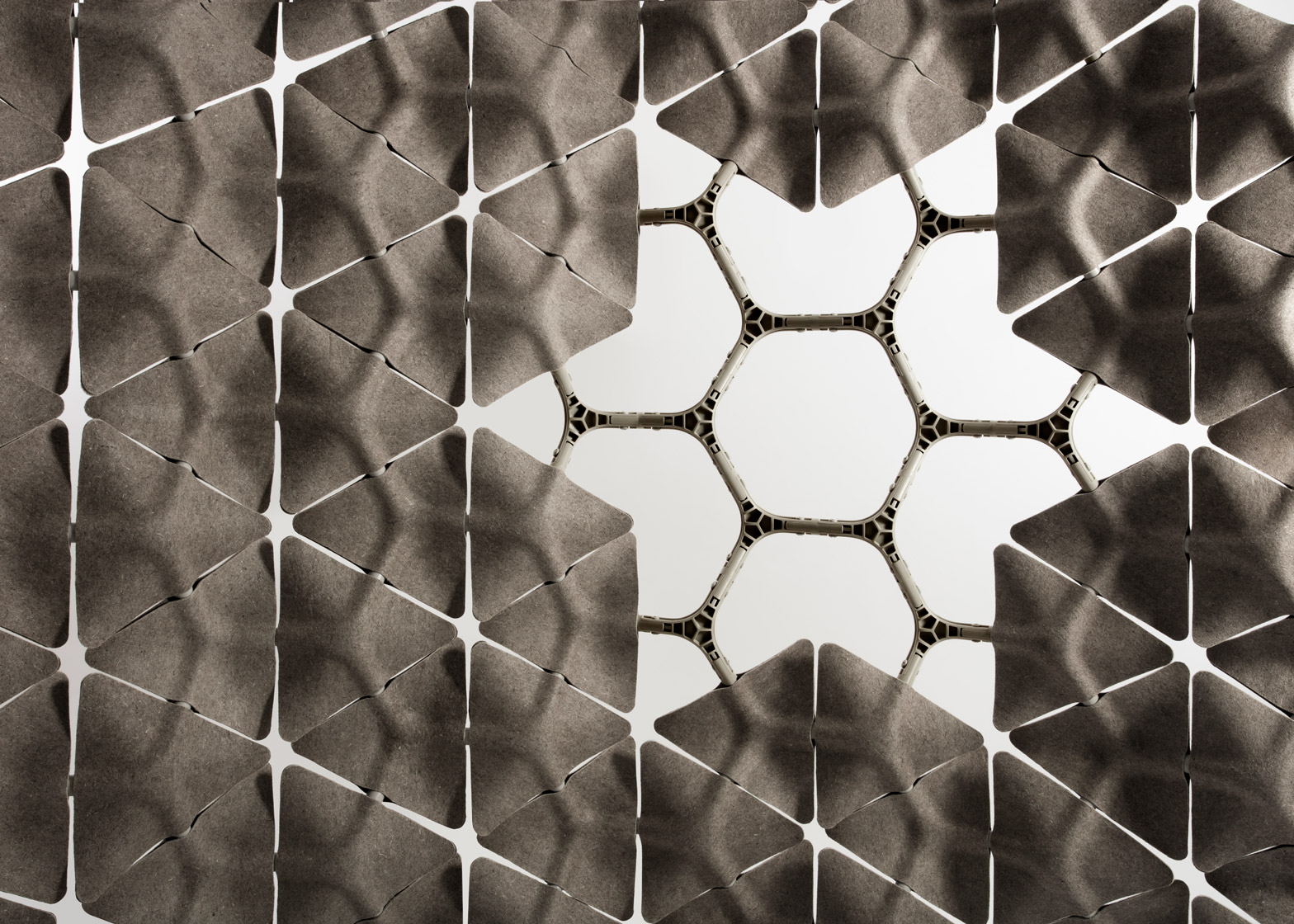

The sturdy, stiff fibres that kind the surface of the stem can be utilized to provide bioplastic merchandise together with automotive components and even wind-turbine blades and cladding panels, Shah stated.

“With the hemp bioplastic cladding panels, we discover that they’re an acceptable different to aluminium, bitumen-plastic and galvanised metal panels, requiring solely 15 to 60 per cent of the vitality in its manufacturing.”

The shives, that are the woody interior a part of the stem, can be utilized to make “hempcrete“, a non-load-bearing wall infill and insulation materials.

Shah identified that in distinction to standard agriculture, which emits massive quantities of carbon, hemp farms do the other.

“Agricultural land within the UK, on common, emits round 3 tonnes of CO2 per hectare per 12 months,” he stated. “Hemp gives an unimaginable scope to develop a greater future.” As well as, hemp produces extra usable fibres her hectare than forestry.

“We will produce bioplastics that may exchange fibreglass composites”

Shah not too long ago collaborated with film-maker Steve Barron, who has transformed the 53-acre Margent Farm in Cambridgeshire to hemp manufacturing and used the crop to build his own house.

The farm grows industrial hemp organically, which additional reduces emissions in comparison with standard agriculture, the place between 30 and 40 per cent of emissions come from fertilisers and pesticides.

Shah is working with the farm to develop new carbon-negative supplies that might be utilized in manufacturing and development.

“With Margent Farm’s hemp fibres, and utilizing 100 per cent bio-based resins, we will produce bioplastics that may exchange fibreglass composites, aluminium and different supplies in a spread of purposes,” he stated.

“We will use the wealth of textile science information that people have gathered over 1000’s of years to provide a spread of textile fibre composites with properties appropriate for non-structural merchandise.”

Carbon revolution

This text is a part of Dezeen’s carbon revolution collection, which explores how this miracle materials might be faraway from the ambiance and put to make use of on earth. Learn all of the content material at: www.dezeen.com/carbon.

The sky {photograph} used within the carbon revolution graphic is by Taylor van Riper by way of Unsplash.