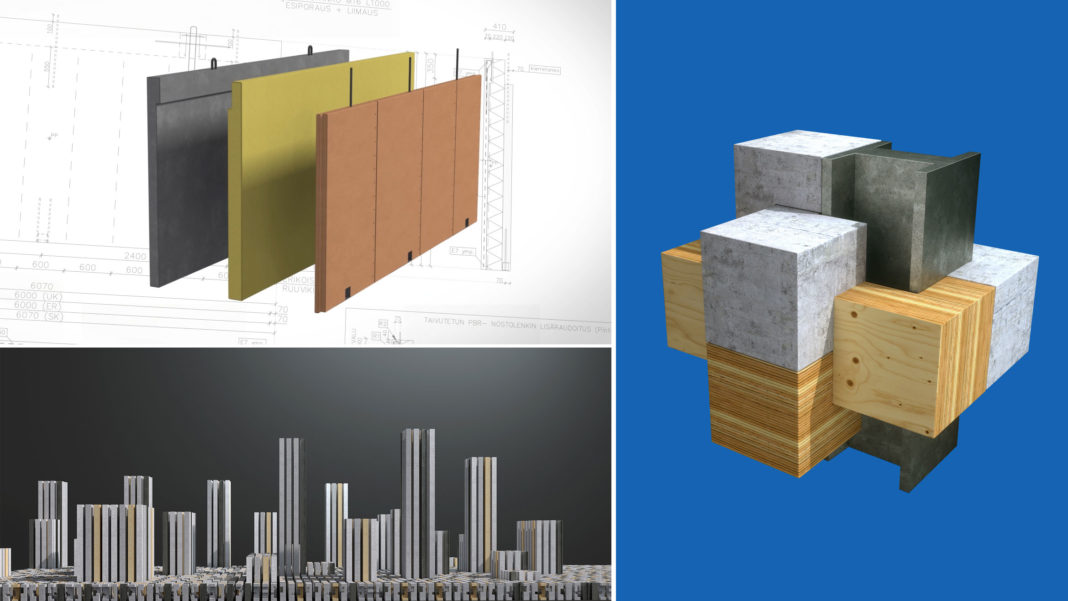

Metsä Wooden and its companions have designed a hybrid sandwich wall component that it says will renew offsite building, providing “a sustainable approach of constructing”.

The innovation combines concrete with Kerto LVL (laminated veneer lumber). The primary building undertaking to make use of the weather is Metsä Fibre’s Rauma sawmill.

Combining concrete and Kerto LVL, the hybrid sandwich wall components supply a simple method to substitute typical concrete sandwich components, the favored wall component in residential multi-storey buildings in Nordic international locations.

“The hybrid sandwich wall component helps to extend the share of wooden to construct extra sustainable buildings effectively,” stated Jussi Björman, director, enterprise building at Metsä Wooden. “This joint improvement is our effort to assist the development trade,”

Metsä Wooden partnered with Finnish building and structural design corporations to design the optimum hybrid sandwich wall component.

Precast component producer Lipa-Betoni noticed the potential of the hybrid components.

“The hybrid sandwich wall component is a superb alternative,” stated Satu Lipsanen, CEO of Lipa-Betoni. “We search for a brand new market with a product, which can be utilized in the identical approach than concrete sandwich components.”

“As Kerto LVL is a light-weight materials, the hybrid sandwich wall components will probably be sooner to provide on the manufacturing facility and transport to the location, and even the transport emissions will lower because of the gentle load. The sunshine components are additionally simpler to raise,” stated Mr Björman.

He additionally stated that new easy-to-produce building options are wanted to show the trade in a extra sustainable route.

“Round 1 million m2 of concrete wall components are produced yearly in Finland. Their load-bearing core creates 45,000 tons of CO2 emissions. If all concrete partitions have been changed with hybrid sandwich wall components, CO2 emissions would lower by 30,000 tons a 12 months and 95,000 tons of carbon can be saved,” stated Mr Björman.

Metsä Fibre’s new Rauma sawmill is the primary building undertaking the place the hybrid sandwich wall components will probably be used. Skanska is the primary constructor of the mill undertaking. The weather will probably be produced at Lipa-Betoni’s manufacturing facility in Pieksämäki, Finland, and put in this month.